Wastewater Treatment Plants

LUS currently has four wastewater treatment plants: South with a capacity of 7 MGD, East with a capacity of 4 MGD, Ambassador with a capacity of 6 MGD, and Northeast with a capacity of 1.5 MGD. All four plants discharge into the Vermilion River. Operators perform daily rounds to check equipment, gauges, and flow to ensure everything is operating properly. They also frequently run ammonia and PH tests, which is a good indicator of untreated wastewater. All tests are logged and analyzed to resolve any issues that may arise.

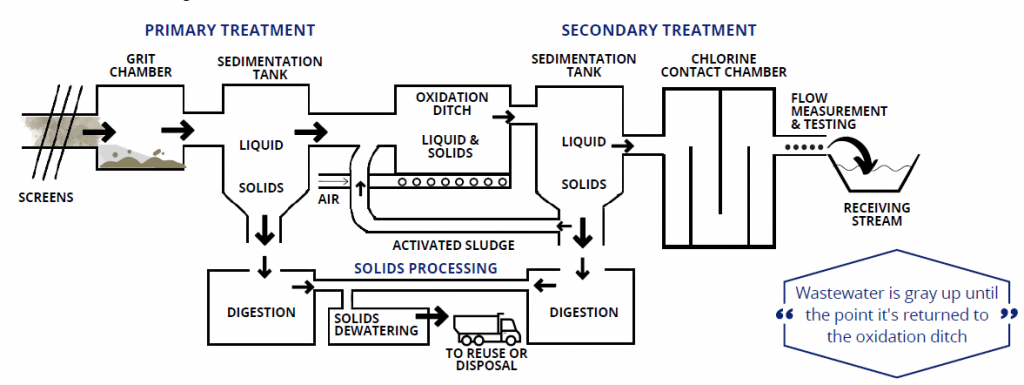

Primary Treatment

Lift stations direct wastewater to the plants where it goes through bar screens to remove anything not treated, such as rags, trash, and leaves. The wastewater then travels through the grit chamber to settle rocks, sand, and other heavy materials at the bottom of the tank for removal by a pump. Operators periodically probe and drain the tank to remove any leftover grit from the bottom of the tank.

After the grit chamber, it moves onto pre-treatment, where grease and oils that float to the top are removed by a skimmer. The next stage is the oxidation ditch (OD), and, in this stage, air is injected into the wastewater by blowers, completing the bulk of the wastewater treatment.

Secondary Treatment

In the final clarifier, solids (aka sludge) settle on the bottom of the tank. The sludge will be removed by a pump and returned to OD, which is a process called activated sludge.

The clear water goes to the chlorine contact chamber to be disinfected. The contact chamber has many walls to slow down the flow so that the chlorine can kill off any bacteria before re-entry into the river. SO2 is then added to the water to remove the chlorine to not affect water life and is then returned to the Vermilion River.

The final destination for the solids is the process of adding polymer and squeezing the water out of it. Once ready, it’s put on a truck and brought to farmers’ lands to be used as fertilizer.